Designing a distribution centre requires a strategic approach that blends efficiency, cost-effectiveness, and adaptability. The goal is to create a facility that can meet the demands of a dynamic supply chain while remaining resilient to future challenges and changes. Here are five critical considerations when planning your distribution centre design.

Understanding Your Requirements

The first step in any successful project is understanding the requirements. This principle is especially true when it comes to designing a distribution centre. Before starting any design work, you must analyze and specify your needs. These requirements can range from the types of products you’ll be storing, their size, weight, fragility, and handling requirements, to the volume of goods you’ll be dealing with. Your design should cater to these specificities to ensure smooth operations.

Space and Budget Allocation

It’s crucial to maximize the use of available space and allocate your budget wisely. Financial considerations should include not only the initial design and construction costs but also ongoing operational expenses. Remember, cheaper isn’t always better if it compromises functionality or long-term efficiency.

Workflow and Process Design

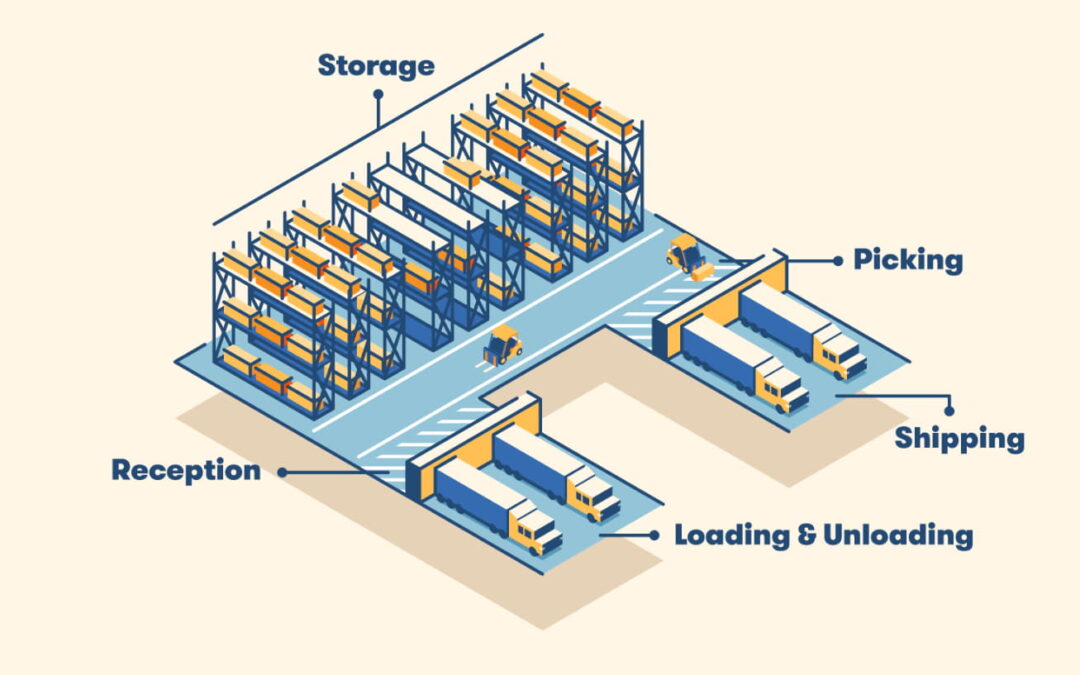

This element involves planning the flow of goods through the facility, from receiving to storage, picking, shipping, and finally, loading and unloading. A well-designed workflow can significantly enhance productivity, reduce errors, and improve overall performance.

During this stage, supply chain consulting can provide valuable insights into best practices and innovative solutions. Experts in this field can help identify potential bottlenecks, suggest automation opportunities, and offer advice on optimizing processes for maximum efficiency.

Flexibility and Scalability

Distribution centres need to be flexible and adaptable to handle variations in demand, changes in product lines, and expansion of business operations. Therefore, your design should incorporate elements that allow for easy modifications or expansions. This flexibility might involve modular storage systems, adjustable racking, or areas set aside for potential future use.

Location Selection

The location of your distribution centre plays a crucial role in its success. Factors such as proximity to transportation routes, regional demographics, labour availability, real estate costs, and customer locations should all be considered. A strategically chosen location can reduce transportation costs, improve delivery times, and increase overall supply chain efficiency.

Conclusion

Effective distribution centre design is a complex process that requires careful planning and consideration of numerous factors. Understanding your requirements, allocating space and budget wisely, designing efficient workflows, ensuring flexibility, and selecting the right location are all key elements in creating a successful distribution centre. By considering these aspects, you can design a facility that not only meets your current needs but is also ready for the challenges and opportunities of the future.