Introduction

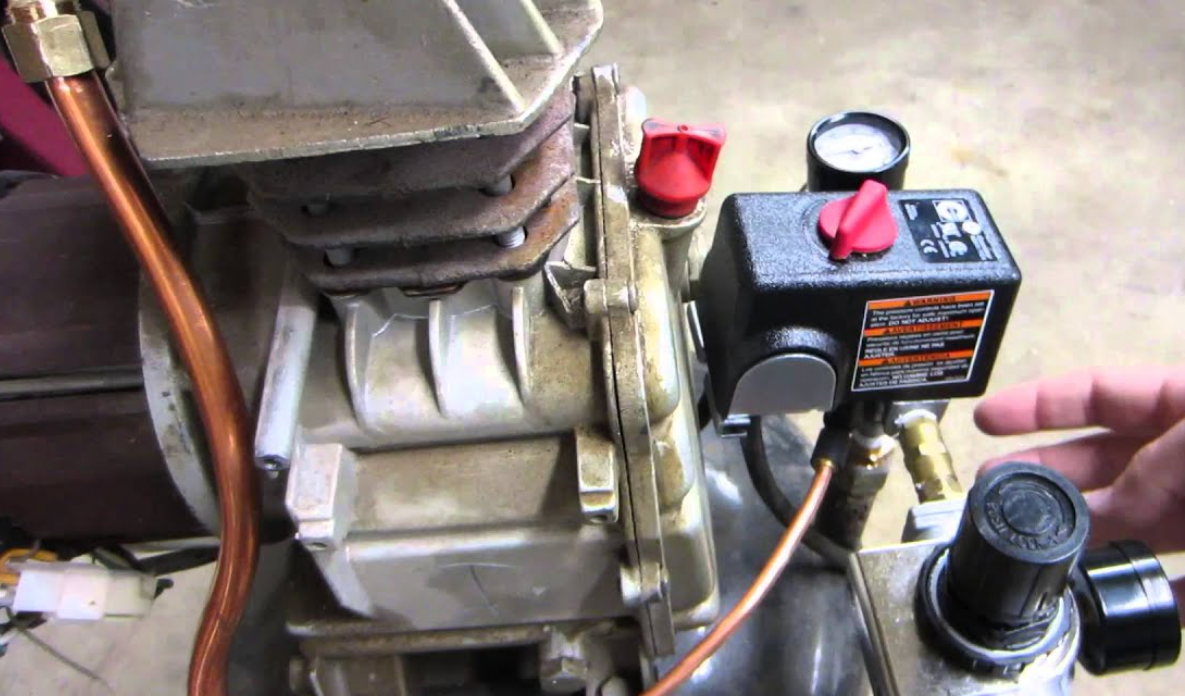

Are you looking for air compressor repair? An air compressor is a simple machine that you need to keep in good condition. If you want to get the most out of your compressor and ensure it lasts for many years, follow these maintenance tips. An air compressor is a simple machine that you absolutely need to keep in good condition. If it breaks down or has a problem, the whole construction site can grind to a halt, which means your crew won’t be able to work efficiently.

Compressed air, just like lubricating oils, needs to stay clean.

Air compressors produce a lot of dust that can damage the compressor. Therefore, if you use compressed air for general cleaning and maintenance around your facility, there must be no oil deposits on the nozzle or in the hose. This will prevent oil from entering your system through dirty hoses and equipment. The same goes with using powered tools such as sanders or grinders.

To maintain constant pressure, the compressor will have to run more often.

This means that the compressor is working harder, which increases its wear and tear. If your air compressor is constantly running, this could cause concern, and you may need professional help with your air compressor repair or maintenance.

Always try to use as short a hose as possible.

Using a short hose can help you avoid the following:

- Kinking. A long hose may get kinked, which reduces its efficiency by slowing down the flow of air. This will put more stress on your compressor and decrease its lifespan. If your hoses constantly get caught on things or tangling around each other, it’s time to buy some new ones!

- Damage from outside forces or objects. Short hoses are less likely to be damaged by outside forces such as people tripping over them or being caught on something like tree branches when moving around your property. They’re also less likely to be damaged due to improper storage in an area where they could be crushed by heavy items like toolboxes or lawnmowers (this is especially important if you have an above-ground unit).

- Loss of efficiency because they’re harder to use effectively while working outdoors with them attached directly onto the air compressor itself; this means having fewer options available for connecting different types of tools compared with using longer ones that come pre-attached with multiple connectors, so all you’d have left was attaching whatever else needs accessorizing after already having gotten everything ready ahead time before starting work!

Please ensure the entire hose is free of paint or dirt buildup before connecting it to any tool.

To ensure that your tools are working safely, you should ensure that the entire hose is free of any paint or dirt buildup before connecting it to any tool. This will help prevent accidents and injuries caused by tools that don’t work properly. Next, use a wire brush to remove dirt from the hose and a hose cleaning solution to clean it. You can also use a hose pressure gauge to check for leaks in the hose if you have one available.

With proper care and maintenance, your air compressor can last long.

If you have an air compressor in your home or garage, it’s important to ensure that the machine is kept clean and maintained. A working air compressor can be a great tool for many applications, but if it isn’t properly cared for, it can cause damage and even lead to fire hazards.

Air filters should be cleaned regularly by removing them from their housing and blowing out any buildup with compressed air. This will prevent dirt from entering the motor and causing damage. The same goes for all other components of your system, including hoses, couplings and fittings, and tools used with compressed air systems (e.g., drills).

Conclusion

All in all, air compressors are a valuable tool to have in your workshop. However, ensure that you follow the correct procedures for maintaining and keeping it clean when using it. For more information visit our Website.